Shoveling through a (Snow) Pile of Work

- mityoyo2018

- Nov 7, 2018

- 2 min read

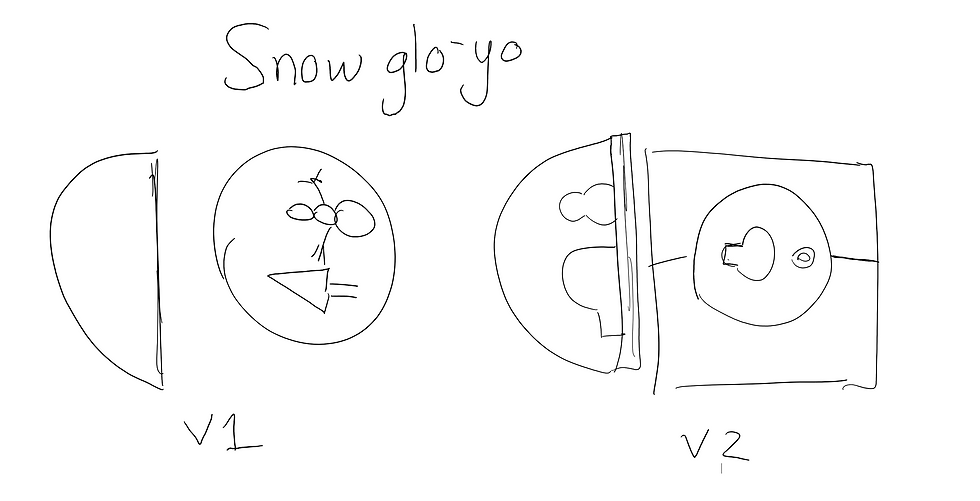

This week we focused on finishing machining the molds and we began to print our first parts.

Body and Snap Ring

This week we continued to work on printing the body and snap ring as we know that the sooner we get them to fit well the sooner we can fit everything together. We were having issues getting the fit right as the shrinkage of the body was much larger than the ring. Therefore we went in with the lathe and opened up the diameter of the body. After doing that and playing around with injection molding setting we were able to get a fit that can stand a good amount of force.

Thermoformed Dome and Stand

Along with this we focused of making sure the dome both printed well and fit into the body-snap ring joint. After perfecting the thermoforming parameters and learning how to set up the punch and punching out the dome we found that it slightly too small. More importantly the punch was hard to center with the current design. Therefore we went ahead and added a small lip in the mold at the right height to create a centering device for the punch. We also used this time to increase the size and depth of the snowflakes a little bit to add to the aesthetics of the piece.

For the dome we decreased the overall height and added more vacuum holes which helped fix the problems we saw last week.

Other Molds

We are also in the process of machining the other molds but due to the high level of detail they are still in the works. One mold in particular, the snowman cavity, will take over 9 hours of machining time so we are focusing on using the HAAS Mill to create the part overnight.

Comments